Agro2Circular

The Confederation of Lithuanian Industrialists is part of a large European Consortium implementing the Horizon 2020 project Agro2Circular – Territorial Circular Systemic Solution for the Upcycling of Residues from the AgriFood Sector

The Confederation of Lithuanian Industrialists is part of a large European Consortium implementing the Horizon 2020 project Agro2Circular – Territorial Circular Systemic Solution for the Upcycling of Residues from the AgriFood Sector

Call identifier: H2020-LC-GD2020 (Building a Low-Carbon, Climate Resilient Future: Research and Innovation in Support of the European Green Deal) LC (IA)

Horizon 2020 (2014-2020; Framework Programme 8) / Horizon Europe (2021-2027; Framework Programme 9) is the EU’s key funding programme for research and innovation with a budget of 77 billion in the period 2014-2020 and 95,5 billion in the period 2021-2027.

Duration of the Project: 36 months (October, 2021 – September, 2024)

Project Coordinator: Asociacion Empresarial de Investigacion Centro Tecnologico del Calzadoy del Plastico de la Region de Murcia (CETEC) (Technological Center of Footwear and Plastic of the Region of Murcia) (Spain), www.ctcalzado.org

Project No.: 101036838

Project partners:

Nº |

Participant organisation name/Main role |

Short n. |

Type |

Country |

1 |

Centro Tecnológico del Calzado y del Plástico-Coordinator. Plastic wastes characterisation & pre-treatments for enhancing enzymatic attack, plastics mechanical recycling, PHBV bioplastic compounding & transformation at small scale, plastics & bioplastics characterisation, recyclability & biodegradability studies. https://www.ctcalzado.org/en_US/ |

CETEC |

RTO |

ES |

2 |

Green World Compounding, SL- Plastics waste decontamination & mechanical recycling, development of high barrier recyclable plastics compounds, leader of integration of pilot technologies. http://www.gwplastics-group.com/ |

GWC |

SME |

ES |

3 |

Saperatec GmbH-Physical delamination of multilayers containing aluminium https://www.saperatec.de/en/ |

SAPE |

SME |

DE |

4 |

Iris Technology, SL- Optical sorting of multilayers https://www.iristechnologygroup.com/en/ |

IRIS |

SME |

ES |

5 |

Universität für Bodenkultur- Modification of recycled aluminium from multilayers https://boku.ac.at/en/ |

BOKU |

UNI |

AT |

6 |

Mellizyme Biotechnology Ltd – Enzymatic degradation process of PET/PE multilayers |

MELLI |

SME |

UK |

7 |

Cetec Biotechnology, SL- PHBV bioplastic production & pilot scale up http://www.cetecbiotechnology.es/ |

CETBIO |

UNI |

IT |

8 |

University of Milano-Bicocca- Biotransformation of PET/PE enzymatic degradation products into building blocks for cosmetic https://en.unimib.it/ |

UNIMIB |

RTO |

IT |

9 |

Universidad de Alicante – Carotenoids for cosmetics & PHBV bioplastics production https://www.ua.es/ |

UA |

UNI |

ES |

10 |

Wetsus- European centre of excellence for sustainable water technology – Water sustainability approach in A2C processes, plastics decontamination process, PHBV bioplastic green extraction https://www.wetsus.nl/ |

WETS |

RTO |

NL |

11 |

Regenera Levante, SL – Energy sustainability approach in A2C processes https://regeneralevante.com/ |

REG |

SME |

ES |

12 |

Centre of Expertise Water Treatment – Water sustainability approach in A2C processes, plastics decontamination process https://www.cew.nl/en/ |

CEW |

RTO |

NL |

13 |

Centro Tecnológico Nacional de la Conserva – Agrifood wastes characterisation & pre-treatments, Research on optimal green hybrid extraction & purification routes for bioactives. https://ctnc.es/ |

CTNC |

RTO |

ES |

14 |

Agrotransformados, SA (MOCITOS) – Food processor – Agrifood (grapes, artichoke, apples) & multilayer packaging wastes provider. End user (development & validation of food formulations for juices, jams & compotes using the A2C bioactives in real environment) https://mocitos.es/en/ |

MCT |

SME |

ES |

15 |

Laboratorios Almond, SL – Food processor- Agrifood (grapes, apples) & multilayer packaging wastes provider, End user (development & validation of food formulations for vegetable desserts using the A2C bioactives in real environment) www.naturgreenfood.com |

ALM |

SME |

ES |

16 |

Proexport-Association of Producers and exporters from Region of Murcia. Agricultural primary sector representative; Agrifood (cauliflower, broccoli, artichoke) & agricultural films wastes provider; socioeconomic assessment, A2C CE Action Plan; A2C model, public engagement. https://www.proexport.es/ |

PROEX |

NPO |

ES |

17 |

DMC Research Center, SL- Development & pilot scale up of green extraction+enzymatic hydrolysis+micrawave-assisted extraction. Evaluation of the bioactive extracts. End user (development of nutraceuticals formulations using the A2C bioactives in real environment |

DMC |

SME |

ES |

18 |

Citromil, SL-Food processor- Agrifood (citrus) & multilayer packaging wastes provider, development & pilot scale up of green extraction+ultrasound-assisted extraction. End user (development of food formulations for juices with A2C bioactives,real environment) https://citromil.net/ |

CITRO |

SME |

ES |

19 |

MKS Instruments Italy, SRL. – Development of microwave extraction technology. https://www.mks.com/ |

MKSI |

LI |

IT |

20 |

Experimental Station for the Food Preservation Industry- Research on purification & stabilisation of the bioactive extracts. |

SSICA |

RTO |

IT |

21 |

Senior Europa, SL (Kveloce I+D+i)- Systemic approach manager-public engagement leader, A2C model (socioeconomic, policy, governance & impact assessment), capacity building |

KVC |

SME |

ES |

22 |

Polibienestar. Universitat de Valencia- Public engagement, A2C model (socioeconomic, policy, governance), capacity building https://www.uv.es/ |

UVEG |

UNI |

ES |

23 |

Fundación Cajamar- Financing entity linked to agrifood sector; A2C CEBMs financing needs, A2C model (private funds); public engagement, capacity building. https://www.fundacioncajamar.es |

CJM |

NPO |

ES |

24 |

Comunidad Autónoma de la Región de Murcia: Public engagement, A2C model (Public financing, policy & governance), A2C Circular Action Plan, capacity building https://www.carm.es |

CARM |

Public |

ES |

25 |

Asociación Española de Normalización- A2C Standardisation activities, public engagement, A2C model (regulations), capacity building. https://www.une.org/ |

UNE |

NPO |

ES |

26 |

Fundación Cluster Agroalimentario de la Región de Murcia-Agrifood cluster representative from Region of Murcia: A2C Circular Action Plan, public engagement, A2C model (socioeconomic), capacity building https://www.agrofoodmurcia.com/ |

AGRO |

NPO |

ES |

27 |

European Association of Development Agencies-EURADA- Leading clustering actions, public engagement, A2C model (public financing, policy & governance), capacity building https://www.eurada.org/ |

EURA |

NPO |

BE |

28 |

Bocconi University- Circular economy expert, Circular business models developer, A2C model (socioeconomic, financing), capacity building https://www.unibocconi.eu |

UB |

UNI |

IT |

29 |

VTT Technical Research Centre of Finland Ltd- Environmental externalities, LCA, circularity, benchmarking, A2C model https://www.vttresearch.com/en |

VTT |

RTO |

FI |

30 |

Fondazione ICONS-Outreach manager, Public engagement, capacity building. https://www.icons.it/ |

ICONS |

NPO |

IT |

31 |

Fundación Primafrio- Citizens representative linked with agrifood sector; Local outreach desk, public engagement, A2C Circular Action Plan; A2C model (socioeconomic), capacity building https://fundacionprimafrio.com/ |

PRIMA |

NPO |

ES |

32 |

Instituto de Fomento de la Región de Murcia: Regional development agency, CEBMs public financing, public engagement, A2C model (financing & governance) A2C Circular Action Plan; capacity building https://www.institutofomentomurcia.es/ |

INFO |

Public |

ES |

33 |

Ecotrace Plastic, SL- Leader of development of digital Data Integration System (DIS). https://www.en.ecotrace.es/ |

ECO |

SME |

ES |

34 |

Equmetrics, SL- Watermark impression development for DIS tool. https://equmetrics.com/ |

EQU |

SME |

ES |

35 |

Exus Software, SMLLC- Big Data for DIS tool. https://www.exus.co.uk/ |

EXUS |

LI |

EL |

36 |

EVRYTHNG, Sárl- Blockchain for DIS tool. |

EVRY |

LI |

CH |

37 |

Solplast, SA- End user (development of new recyclable barrier films as alternative to multilayers & biodegradable films for agriculture in a real environment). https://solplast.com/inicio |

SOLP |

LI |

ES |

38 |

Eversia, SA- End user (development of barrier packaging as alternative to multilayers and biodegradable packaging in a real environment). https://eversia.es/ |

EVER |

LI |

ES |

39 |

Lolo Bio Cosmetics, SL- End user (development of new cosmetic formulations using the A2C bioactives in a real environment). https://lolobio.com/ |

LOL |

SME |

ES |

40 |

Tecnoalimenti s.c.p.A- A2C model co-creation; territorial replication of A2C model; public engagement and capacity building https://www.tecnoali.com/ |

TCA |

NPO |

IT |

41 |

Lietuvos Pramonininku Konfedracija- A2C model co-creation; territorial replication of A2C model; public engagement and capacity building https://lpk.lt/en/ |

LPK |

NPO |

LI |

GENERAL AGRO2CIRCULAR (A2C) PROJECT CONTEXT, 4 ASPECTS:

- About one third of the food produced is currently wasted. The fruits & vegetables (F&V) are the group of major contribution to food waste along the food supply chain, rising up to > 40% of waste. However, currently, these F&V wastes are exploited, in the best scenario they are transferred for animal feed, compost or biomass energy fuel. Research on these agrifood matrices reveals them as an excellent source of a wide range of natural bioactive compounds (such as dietary fibre, phenolic compounds & carotenoids) as natural alternatives to synthetic additives for the production of nutraceuticals, functional foods, and cosmetics. However, synthetic additives are still applied due to their high stability and low cost compared to natural alternatives. Methods for obtaining bioactives from F&V, based on non-organic solvents extraction techniques, are not efficient (low yields & purity) and environmentally unsustainable. Green hybrid extraction methods are emerging as great potentially alternatives; however, they still require improvements to be economic, time & energy viable for their industrial implementation.

- Multilayer plastic films are widely used as industrial packaging for the protection of food (2.3Mt/year) and agriculture for crops (0.15Mt/year) due to their unique barrier properties enabling significant extension of food preservation and chemical disinfection of crops in intensive agriculture. They are traditionally composed of multiple high-performance layers: PE, PET, PA or EVOH, but also aluminium. Currently, there is a lack of sorting and recycling technologies for an economic and environmentally sustainable valorisation of these multilayer structures due to the different materials they are made: (i) sorting of complex multilayers is not efficient at waste treatment facilities (aluminium and opaque foils are not identified, multilayers contaminates monomaterial sorted fractions), (ii) recycling of multimaterials is complex, not economically viable, (iii) food films requires decontamination. Being mostly landfilled (34%) or incinerated (66%). As consequence, annually €650M-950M economic value is not recovered for the EU economy, thus circular approaches are needed.

- Digital technologies has been demonstrated as a powerful tool supporting the transition to circular business models. However, the agrifood sector has a low level of digitalization compared to other industrial sectors (13%).

- While there is an increasing number of European initiatives aimed at implementing the circular economy concept, there is still a lack of demonstrated and replicable systemic solutions for the territorial deployment of the circular economy.

THE MAIN OBJECTIVE OF THE PROJECT – the implementation of a territorial systemic solution for the upcycling of most relevant residues in the agrifood sector (fruits& vegetables and multilayers) into high added value products, powered by a digital tool and constructed upon a systemic approach with high replicable/scalable potential.

A2C territorial cluster include all relevant actors united under the common objective of achieving a transition from linear economy to circular economy in the Región de Murcia (Southeast of Spain). This Region is one of the keys players of the European agrifood sector. Our Plan is to join the European best available technologies to solve the identified challenges and demonstrate its effective value as engine of a change in the production model. So technologies and experts from all over Europe (Germany, Spain, Austria, United Kingdom, Italy, The Netherland, Finland, Belgium and Switzerland) join SMEs, Large Industries, RTOs, associations, organizations and institutions in the Region of Murcia to develop a systemic solution based on circular economy criteria producing positive social, environmental and economical impacts.

Further, to ensure that A2C systemic solution and the business model achieve high replicability, our consortium involves organizations from the Lombary Region (Italy) and the NUTS-2 Region of Lithuania, two relevant representative regions of the European agrifood sector. Furthermore, A2C counts with the commitment to be involved in the project activities of 26 clusters from 8 European countries.

A2C will directly contribute to achieve the expected impacts of the topic by increasing the agrifood sector sustainability, generating local/territorial socio-economic & environmental benefits while it increases the security of European key products & materials, contributes to decouple economic growth from resource use and pushes towards climate neutral industries and communities. EU potential benefits will be significant: Reduction of 27,600.5 ktonnes CO2 emissions, 13,098.56 ktonne of primary materials are fed-back into the economy, 2976 quality jobs generated, increasing social behaviour shift towards circularity (10-30%), widely disseminated tools and recommendations fostering circular economy at all replication levels and among all stakeholders relevant to A2C, including citizens. A2C will achieve TRL 6-7 at the end of the project (36-months).

AGRO2CIRCULAR PROJECT HAS 3 MAIN OBJECTIVES:

OBJECTIVE 1: Demonstrating the first value chain for the upcycling of most representative agrifood sector wastes

Aims to demonstrate the technical viability of specific routes for the valorisation of agrifood wastes (fruits and vegetables and multilayer plastics): i) demonstrate the potential of green hybrid extraction, purification & stabilisation routes for the obtaining of high valuable bioactives (dietary fibres, phenolic compounds & carotenoids). The aim is to achieve high extraction yields and high purity bioactives with high stability for new foods, nutraceuticals & cosmetics; ii) demonstrate the potential of the synergistic combination of sorting, physical delamination, enzymatic depolymerisation, decontamination & mechanical recycling for the multilayers recycling and biotransformation processes & extensional flow mixing for the upcycling of the recycled multilayers. The aim is to obtain a range of high barrier recyclable compounds as alternative to current multilayers in food packaging & agriculture, PHBV bioplastics compounds for biodegradable food packaging & agriculture and carotenoids for cosmetics; iii) demonstrate the potential of the ICT technologies as key tool for the implementation of circular solutions. The aim is to implement the traceability of process and products and to develop a predictive tool for recovery processes through an online technological platform named Data Integration System-DIS. Expected impact: 1. A2C high contribution to the decoupling of economic & human activities from the consumption of finite resources & GHG emissions, 2. A2C contribution to improve sustainability and circularity of clusters’ economic sectors, natural ecosystems, management and valorisation of local resources.

OBJECTIVE 2: Providing to the A2C technological solution the circular systemic approach by building a multidimensional model enabling the solution territorial deployment and its replication and scalability.

Entails to: i) develop and demonstrate the A2C circular business models and analysing financing opportunities; ii) involve relevant stakeholders (public engagement) to build together (co-creation) a common view around the A2C systemic solution model at local/territorial and EU level; iii) identify, analyse and quantify the territorial economic, social & environmental barriers/benefits and the relevant indicators related to the respective cluster; iv) construct the A2C multidimensional model (includes also relevant factors: governance, regulation, policy, financing, etc.) providing the demonstration of the cluster towards circularity, while designing specific tools to foster the replicability&scalability of the A2C model; v) co-create/demonstrate the model in two EU agri-food clusters of Italian and Lithuanian regions, enabling the territorial deployment of the circular economy in both; vi) Validate the applicability of the model and the tools delivered, through cross-fertilization with other agrifood clusters and relevant stakeholders (see support letters). Expected impact: 3. Emergence of circular business opportunities and a structured pipeline of investment projects; 4. Creation of jobs in the short to medium term.

Objective 3:Maximizing project impacts and facilitating A2C systemic solution replication& scalability

Entails to: i) design the communication & dissemination strategy and content packaging to support the public engagement, the project sustainability and the widespread of results; ii) engage in cooperation and mobilization of all relevant stakeholders at local and EU levels, including those for further commercialisation; iii) support the Public Engagement strategy through specific and tailored actions; iv) deliver a framework for autonomous learning & capacity building. v) develop a comprehensive exploitation strategy for the A2C cluster. vi) widespread general knowledge about food and plastic waste and the circular economy at all levels. Expected impact: 5. Increased circular and climate-neutral practices among citizens and participation in systemic solutions (together with Objective 2); 6. More effective development of circular solutions through knowledge transfer; 7. More effective widespread uptake and easier replication, scalability and visibility of circular systemic solutions.

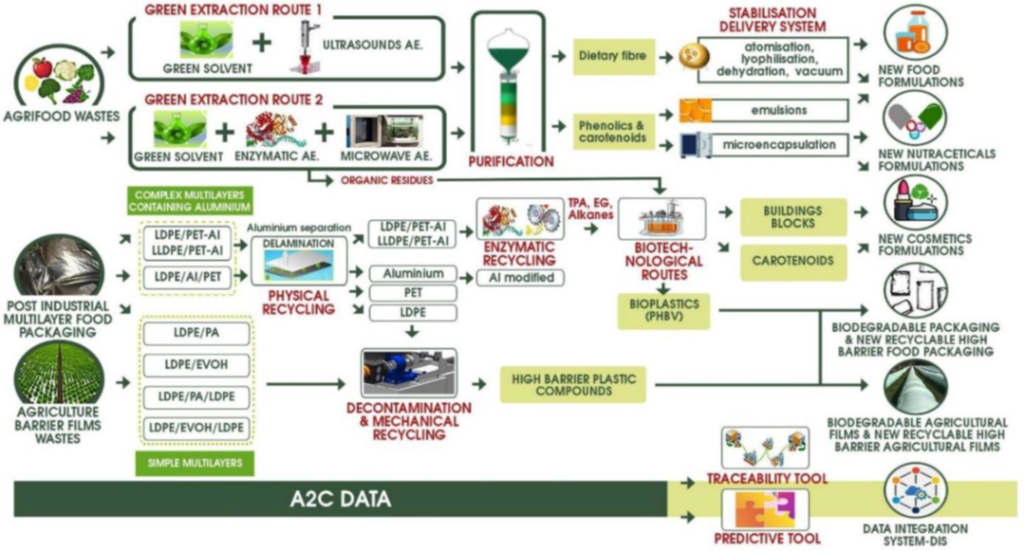

The following Figure 2 summarises A2C project approach to achieve these objectives:

A2C will allow for the first time the upcycling of fruits & vegetable agrifood wastes (F&VW) and non-renewable multilayer plastics into new high added value products with application in the food, nutraceutics and cosmetic sectors, and to demonstrate its implementation at pilot scale and the validation of the final products in a real environment. This solution will be powered by an intensive use of digital technologies enabling the traceability of all processes, providing a valuable decision tool and fostering citizen’s acceptability through data availability and transparency. Moreover, A2C solution will be constructed upon a systemic approach delivering a multidimensional model for A2C territorial adoption and highly replicable/scalable (validated at EU level) whose adoption/replication will be boosted through delivering at local/EU levels adequate tools.

Following is described the A2C whole systemic solution and Figure 3 represents the technological solution.

1.Extraction and purification of bioactive substances from Fruit and Vegetables (F&V) wastes by a hybrid strategy of green solvents and sustainable advance extraction technologies.

1.1. A2C has selected these F&V wastes since two perspectives: i) great potential to be valorised having wide variety of bioactive compounds of interest for the food, cosmetic and nutraceutics industries ii) represent 32.7% of the EU total harvested production of F&V and a high volume of wastes that currently are not exploited. Result: Optimal bioactive compounds from F&V wastes for food, cosmetic & nutraceutics market needs.

Product |

Waste (% of generation) |

Target substances |

Citrus |

Peel, pulp, skins, seeds (50-60%) |

Dietary fiber. Phenolics: flavonoids (hesperidin, eryocytrin, quercetin), caffeic acid. Carotenoids: β-carotene, lutein, lycopene |

Apples |

Peel, seeds and cores, exhausted pulp (10-15%) |

Dietary fiber. Phenolics: flavonoids (quercetin, catechin, epicatechin), chlorogenic acid, caffeic acid |

Grapes |

Pomace (peel, seeds, stems and pulp residues) and grape remains (25%) |

Dietary fiber. Phenolics: flavonoids (quercetin, catechin, epicatechin), resveratrol |

Artichoke |

Leaves and bracts (60-65%) |

Dietary fiber. Phenolics: Cynarin, chlorogenic acid, caffeic acid. Carotenoids: β-carotene, neoxanthin, lutein |

Cauliflower |

Stems, florets not suitable for marketing, and leaves (40%) |

Dietary fiber. Phenolics: flavonoids (quercetin, kaempferol), caffeic acid |

Broccoli |

Stems and florets not suitable for marketing, leaves (25-30%) |

Dietary fibers. Phenolics: flavonoids (quercetin, kaempferol), chlorogenic acid. Carotenoids: α-carotene, β-carotene, lutein |

1.2. Innovative extraction strategies for bioactive substances. From the F&V wastes of 1.1. we will implement specific extraction routes according to the target extracts and the required purity their final applications, as shows table 2. Result: Technically efficient and economically viable extraction & purification routes.

| Partner | Extraction route | Purification tech. | Expected results | Use |

| CITRO

CTNC SSICA |

Green solvents + ultrasounds assisted extraction | Membrane Filtration | Dietary fibre (Yield≥60%, Purity ≥70%) | Food |

| Membrane filtration+ Adsorption | Phenolic compounds & Carotenoids (Yield≥60%, Purity ≥70%) | Food | ||

| DMC

CTNC SSICA MKSI |

Green solvents + enzymatic hydrolysis + MW assisted extraction | Membrane filtration | Dietary fibre (Yield≥70%, Purity ≥80%) | Food; Nutraceuticals |

| Phenolic compounds, Carotenoids (Yield≥70%, Purity ≥80%) | Membrane filtration+ Adsorption | Food;

Cosmetics;Nutraceuticals |

- Production of a range of new formulations using the bioactive substances extracted from wastes for their application in cosmetic, nutraceutics and food. 2.1. Design a specific strategy in each case to achieve high stability of the extracts for further industrialisation. Result: Extracted substances (dietary fiber, phenolic compounds & carotenoids) with high stability ready for application. 2.2. The high stable extracted bioactive compounds will be validated in a real environment by end users preparing formulations to demonstrate our solution in operational environment (TRL7). Result: Prototypes for food & nutraceuticals (3000L vegetable desserts, 2000L enriched juices, 20.000 Kg-juices&jams, 1000L nutraceuticals), and cosmetic (1 kg antioxidants formulations).

- Recycling of the multilayer plastics coming from agriculture and post-industrial packaging. 3.1. Optical sorting of the multilayers by a synergistic combination of technologies. Result: Sorting the different multilayers into families: 1 (LDPE/EVOH-packaging, LDPE/EVOH/LDPE-agriculture), 2 (LDPE/PA-packaging, LDPE/PA/LDPE-agriculture), 3 (LLDPE/PET-Al, LDPE/PET-Al both packaging), 4 (LDPE/Al/LDPE-packaging). 3.2. Physical separation of the Aluminium from the multilayers based on SAPE patented delamination technology. Result: The separated flows LDPE/PET, LLDPE/PET, LDPE, PET and Al. 3.3. Enzymatic depolymerisation of the PE/PET multilayers by a synergic strategy of customisation of enzymes and plastic wastes pre-treatments. Our partner MELLI has tested the first known enzyme (MELLI plasticase applied for patent protection on) in the world capable of degrading polyethylene (PE) and polyethyleneterephtalate (PET) at high rates (24 hours). Moreover, a pre-treatment step to enhance enzymatic attack will be implemented. Result: Alkanes, TPA & EG products. 3.4. Plastics decontamination for the reintroduction of the recycled plastics into the agrifood value chain (packaging and agricultural films) by 3 step process of washing, micro/nanoplastics separation and vacuum extrusion. Result: Plastics materials decontaminated (>99%) before mechanical recycling. 3.5. Aluminium purification and treatment for reuse. Aluminium from the physical separation will be chemically modified. Result: Al achieves optimal compatibility and dispersion in a polyethylene matrix. 3.6. Development of processable recycled plastic compounds. The simple multilayers (families 1: LDPE/EVOH, LDPE/EVOH/LDPE & 2: LDPE/PA, LDPE/PA/LDPE) and the plastics monomaterials obtained from the physical recycling (LDPE, PET) will be formulated for their application in food packaging and agricultural films. Result: LDPE/EVOH, PE/PA, LDPE/EVOH/LDPE, LDPE/PA/LDPE, LDPE, PET processable.

- Upcycling of the recycled plastics coming from agriculture and post-industrial packaging to obtain high added value materials. 4.1. Upcycling of enzymatic degradation products (alkanes, TPA, EG) by biotransformation to obtain high adde value building blocks for cosmetic: (1) Alkanes. Result: ω-hydroxy-acids (2) Terephthalic acid-TPA. Result: protocatechuic acid. (3) Ethylene glycol-EG. Result: glycolic acid. 4.2. PHBV bioplastics and carotenoids production by cell factory: The by-products of the previous cell factories in combination with organic waste from the agri-food industry will be used as nutrients. Result: PHBV for its application in flexible packaging and agricultural films, carotenoids for cosmetics applications. 4.3. Development of plastic compounds for food packaging and agriculture. 4.3.1. Development of recyclable high barrier PE plastic compounds as alternative to current non-recyclable multilayers. A2C will develop an innovative route based on a synergistic strategy of compatibilisation and extensional flow mixing generation during the extrusion process to develop blends with high barrier properties.

– The recyclates from post industrial packaging LDPE-EVOH and LDPE will be compatibilised to develop high barrier compounds for food packaging. The aluminium modified will be dispersed in the LDPE/EVOH/LDPE and LDPE/PA/LDPE recyclates coming from the agriculture films for agriculture applications (light diffusion, UV-stability, reflection). Result: High barrier packaging and agriculture disinfection films at small scale. 4.3.2. Development of PHBV bioplastics compounds. The neat PHBV range obtained will be formulated and compounded for their application in the flexible food packaging and agricultural films development. Result: Biodegradable packaging and biodegradable agricultural films at small scale.

- A2C Data Integration System online platform for the traceability of materials and a predictive tool that will allow the selection of the best upcycling option for each material from the existing alternatives. Different ICT technologies will be integrated including cloud thechnology, watermark for hiding information, Quick Real-QR for identifying the information, Big Data and Artificial Intelligence for data processing and statistics, and Blockchain for data security and immutability. Result: DIS platform for traceability, prediction and communication.

- Integration of the A2C technologies at pilot scale up. Demonstrators. 6.1. All the technologies at pilot scale will be integrated in a demonstrator in Murcia (Spain) at GWC, CETBIO, CETEC, DMC and CTNC facilities in order to evaluate their performance in an industrial environment. Result: prototypes from the different technologies validated in industrial environment by the end users achieving TRL6-7 (see Table 4) 6.2. Recovery of by-products generated during the different processes in order to achieve a completely sustainability of the whole A2C upcycling strategy. Result: study of the hotspots to determine a recovery & valorisation strategy in the future industrial scale-up. 6.3 Development of A2C CEBMs and their associated financing mechanisms and integrating them with natural capital accounting. Result: A2C Sustainable and feasible circular economy business models.

- Providing A2C the systemic approach and tools needed for the circularity and territorial deployment, replication and scalability: This approach entails addressing following dimensions/actions through and integrated & coordinated use of Social, sciences and Humanities perspective, as following: 7.1 Design a Public engagement strategy and implement a community based innovation scheme. 7.2 Multidimensional assessment of the territorial/EU context, LCA and circularity evaluation: Identification, analysis and quantification of the socio-economic and environmental benefits (including regulatory, financing, etc), and monitoring the cluster transition towards circular economy. 7.3 Build a multidimensional model for A2C adoption and highly replicable and scalable, co-creation process and validated by other agrifood EU clusters.7.3 Demonstration of the A2C replication and scalability potential through 2 European territories Lombardy (Italy) and NUT-2 (Lithuania) regions cases. Results: Multidimensional model for A2C adoption highly replicable&scalable and the related self-assessment tool; A2C Cluster CE action plan; recommendations for decision makers and valuable knowledge to be transferred.

- Maximizing project outreach and foster circular economy by stakeholders and general public through several activities: Networking, clustering, dissemination and communication activities, development of a training plan for local actors and education services for local communities as well as training modules/guidelines for EU stakeholders, training and knowledge transfer actions, development of A2C cluster exploitation strategy, contribution to standardization. Results: Stakeholders for A2C adoption, replication and exploitation engaged, Citizens/consumers raised acceptance, awareness and knowledge about the circular economy and climate neutral practice/products, A2C transferable knowledge efficiently transferred.

In the project, the Confederation of Lithuanian Industrialists will contribute to:

The refinement of the A2C the systemic approach and tools needed for the circularity and territorial deployment, replication and scalability:

- Will develop a strategy for public involvement, and will use a community based innovation scheme for the implementation guidelines.

- Will carry out a multidimensional analysis of the territorial/EU context, LCA and circularity assessment (identification, analysis and quantification of socio-economic and environmental benefits, including regulation, financing, etc. and monitoring of the cluster’s transition to a circular economy).

- Will perform an analysis of the potential for replication and scalability of the A2C model in the Lithuanian NUT-2 region. Results: Will prepare multidimensional guidelines for the implementation of the A2C model in the selected region of Lithuania and will contribute to the development of a self-assessment tool that complements them; will prepare an action plan for the circular economy of the A2C cluster and implementation recommendations and guidelines for decision-makers, etc.

- Will contribute to the multidimensional guidelines for the implementation of the A2C model in other EU geographical areas (replicability and scalability guidelines).